time:2021-09-07 author:admin

2021

Through ISO9001 quality certification, the company has strict quality control measures.

2021

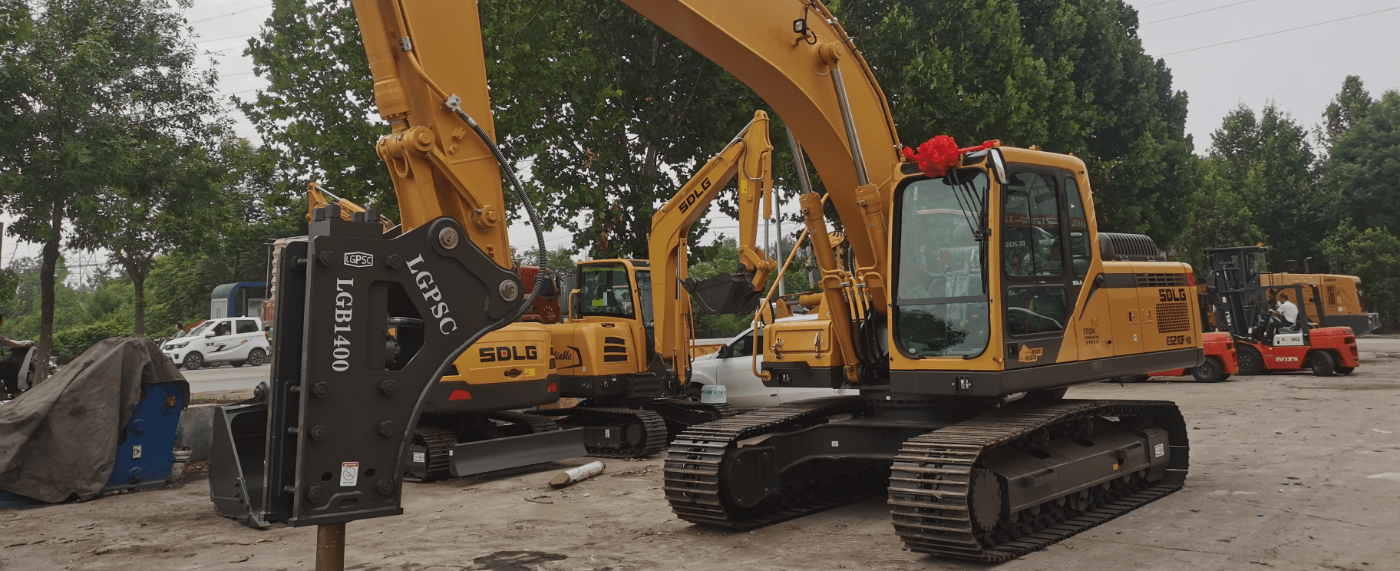

Relying on the hydraulic power device, the hydraulic crushing hammer plays the role of impact, hammering and gravel. Due to a series of advantages of wide application range and high work efficiency, the hydraulic crushing hammer is widely used in mining, metallurgy, transportation, railway, tunnel and other industries

2021

Lao Zhang has been engaged in excavator Service Engineer for 8 years. He is also a teacher. Others call him Lao Zhang. At a quarter past six, the Great Wall Harvard, a service car that had been with him for many years, drove quickly on the road. The back of the car was filled with a car of accessories prepared the night before. The accessories of the car creaked and rubbed all the way. Lao Zhang was thinking that he could go home after using up these accessories smoothly.

Through ISO9001 quality certification, the company has strict quality control measures.

Relying on the hydraulic power device, the hydraulic crushing hammer plays the role of impact, hammering and gravel. Due to a series of advantages of wide application range and high work efficiency, the hydraulic crushing hammer is widely used in mining, metallurgy, transportation, railway, tunnel and other industries

Lao Zhang has been engaged in excavator Service Engineer for 8 years. He is also a teacher. Others call him Lao Zhang. At a quarter past six, the Great Wall Harvard, a service car that had been with him for many years, drove quickly on the road. The back of the car was filled with a car of accessories prepared the night before. The accessories of the car creaked and rubbed all the way. Lao Zhang was thinking that he could go home after using up these accessories smoothly.

Telephone consultation

15165525067

Back to top